Protective coatings in New Trendy products

Since there have been many myths about protective coatings on shower enclosures, how they work and how much they can last, and when they are applied, we decided to write precisely what it looks like in our manufacturing process

How does Active Shield 2.0 and Active Shield coating work?

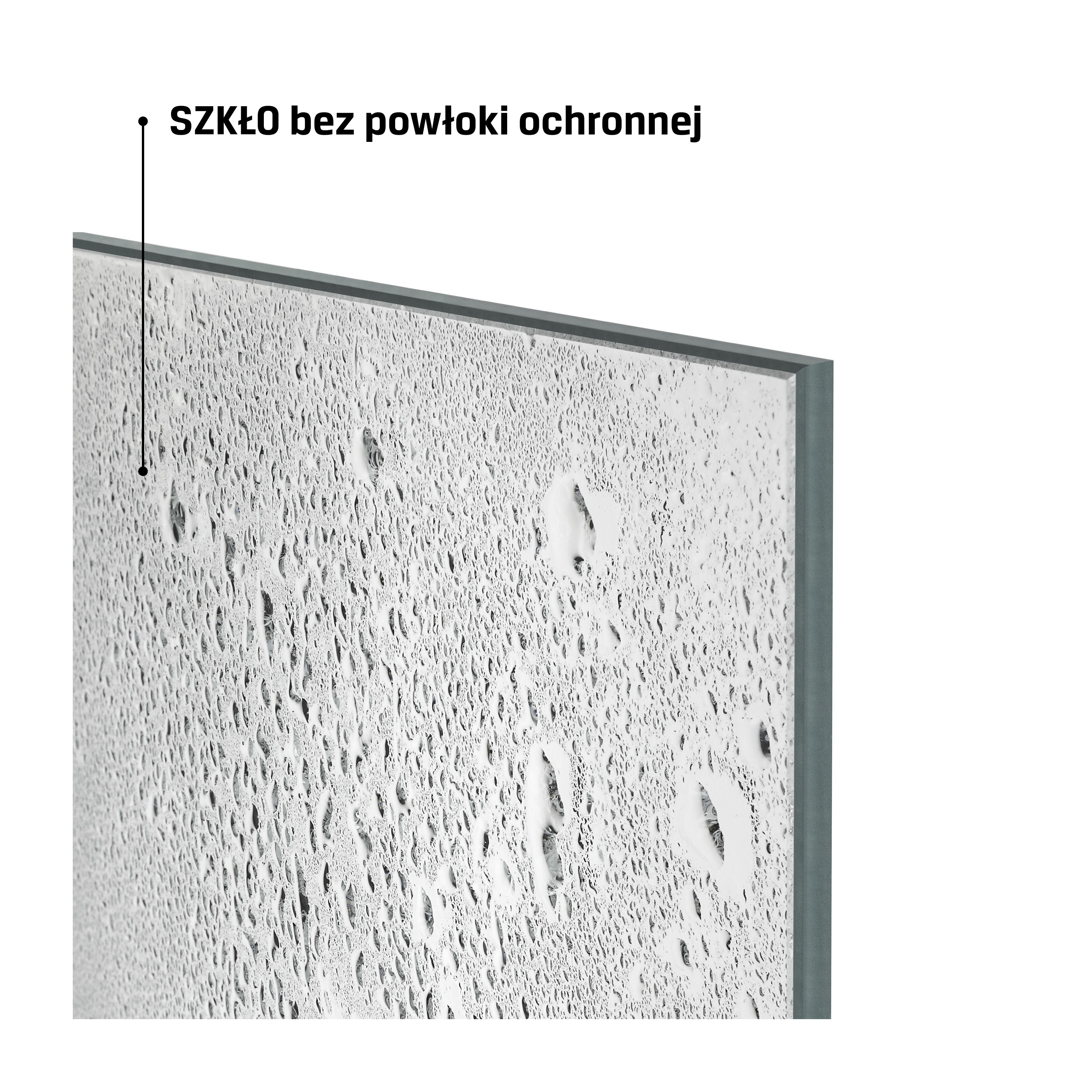

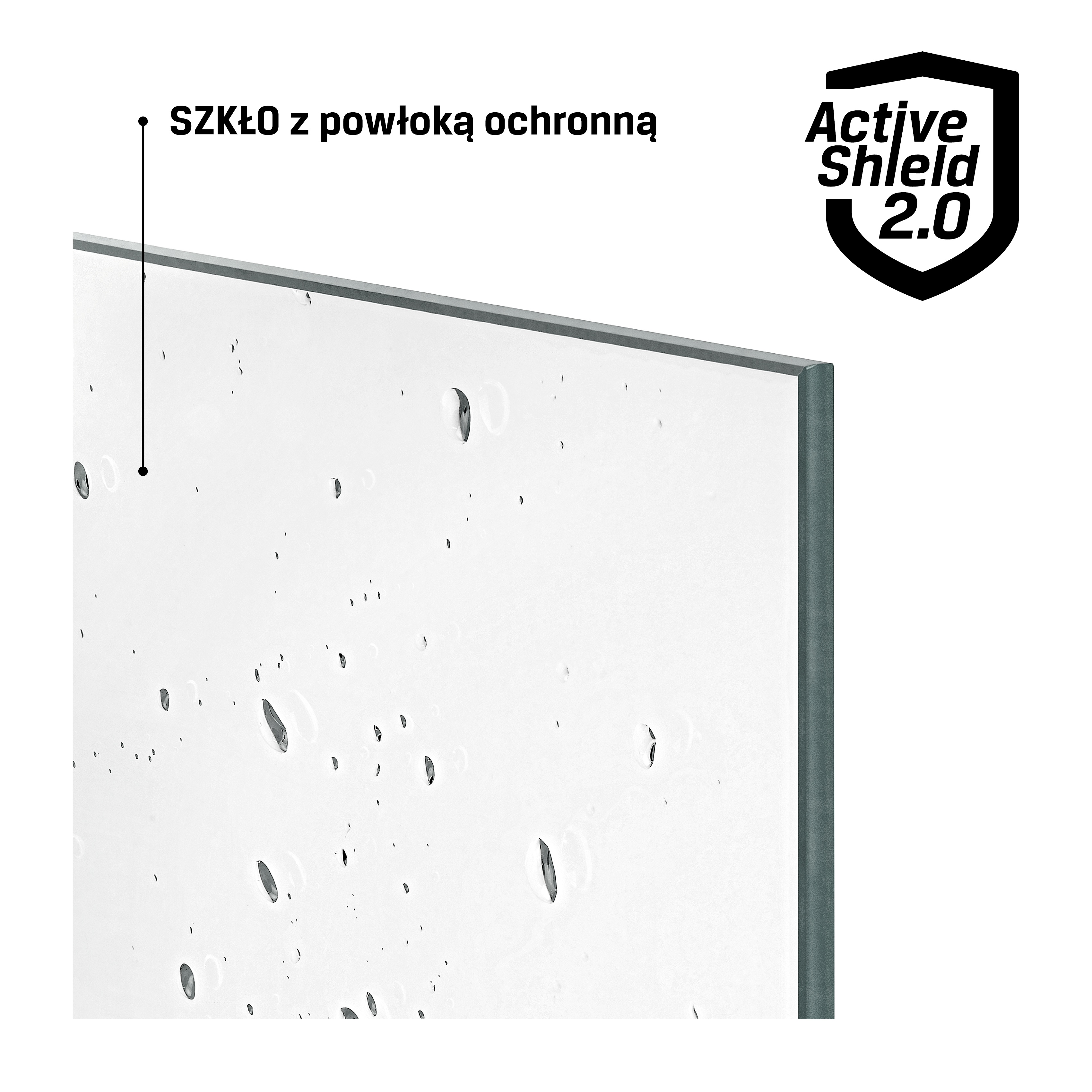

To properly understand the meaning and operation of the coating, it is important to understand at the outset that a sheet of glass (any!) is not, as it appears at first glance, perfectly smooth. The glass has microscopic pores, depressions and irregularities. Although they are imperceptible to the naked eye, they do occur. It is the penetration of small amounts of limescale from water, impurities, cosmetic residues, etc., that causes streaks on the glass, which are visible to the naked eye and, to put it bluntly, do not look good. Acitve Shield 2.0 and Active Shield coatings are designed (in a nutshell) to fill in these microporosities and make the glass perfectly smooth. In other words, the coating acts as an impregnant that fills the aforementioned gaps and irregularities.

What is Active Shield 2.0 and Active Shield coating?

It is a mixture of chemicals that, when applied to the glass of the cabin, produces a hydrophobic layer on its surface, i.e. one that in a sense “reflects” water. By reducing the frictional force between the water droplet and the glass, the effect is that water gathers into larger droplets and flows down the glass faster without leaving streaks.

What is the difference between Active Shield 2.0 and Active Shield coating?

The development of our machinery and the continuous improvement of the production process go hand in hand with our increasing the quality of the products we offer. One of the investments we made recently was the purchase of modern technology that allows us to apply a protective coating to our glass by machine. The new solution allows the glass to be thoroughly cleaned before the coating is applied, applied in a special chamber in a fully automated manner, and then fixed by UV and IR radiation. It is worth mentioning that the fully automated application of the coating provides more precise coverage of the glass surface, no further processing is required, and the coating itself is even more durable than the coating used before. It is worth mentioning that the implementation of Active Shield 2.0 technology has its ecological aspects, especially the reduction of the coating application time and, consequently, a great saving in the energy required for its application. The previous Active Shield coating differs from the new one primarily in its application method. The Active Shield technology was only partially automated, requiring an additional polishing and drying process, which are absent in the new technology.

In the case of Active Shield 2.0 coating, we provide at least a 10-year durability guarantee, of course, if the basic conditions of use are met, i.e….

How to make the coating serve us for many years?

It’s simple. Just follow the manufacturer’s recommendations, and they say:

- rinsing off the remains of cosmetics from the windows after bathing and removing drops of water using a suitable squeegee adapted to the shower cabin

- Regular washing of the cabin with agents recommended by us or others that meet the following conditions: do not contain granular cleaning agents, caustic, abrasive substances, acetone, acids, aluminum compounds, chlorine compounds, alcohol, or organic solvents. In shorter terms: with gentle cabin care products.

- Systematic refreshing of the coating with our preparation or other preparations available on the market, but only from proven manufacturers.

In this way, we can enjoy the clean appearance of the cabin for many years of use.